We released refreshed versions of our Angle Head Wrenches, with nickel plating and refined handles, on April 10, 2024. The Angle Head Wrenches featured in this blog post have been discontinued.

Click here to shop our current Angle Head Wrenches.

We released refreshed versions of our Angle Head Wrenches, with nickel plating and refined handles, on April 10, 2024. The Angle Head Wrenches featured in this blog post have been discontinued.

Click here to shop our current Angle Head Wrenches.

Auzgrip crowfoot wrenches are ultra-compact and designed to pair with a ratchet...They’re not the fastest wrenches to turn, but sometimes they’re the only ones that will fit.

Auzgrip flare nut crowfoot wrenches can fit over hard line tubing and get five points of engagement on soft metal fittings...

Auzgrip service wrenches excel in situations with medium access and are fast and efficient to turn fittings by hand...

Auzgrip angle head wrenches offer the quickest way to continuously turn a fitting or fastener in situations where swing arc is restricted...

All eight examples below use 1 inch wrenches for equal comparison.

If swing arc is limited by obstacles, a wrench with an angled head can be useful...

Of the two crowfoot wrenches, the flare nut style can be flipped over...

If you’re working in tight spaces, crowfoot wrenches can be used with an extension...

The service wrench has the leanest jaw of all the open end access wrenches...

Three of our access wrenches are thinner than our combination wrenches...View Jaw Size Comparison Chart (PDF)

Both crowfoot wrench styles and service wrenches have a drive square to pair with ratchets...

If you need to tighten fasteners or fittings to a specific torque, crowfoot and service wrenches can be used...Torque Conversion Calculator

If you need access wrenches larger than 1-1/2 in. or 38 mm, service wrenches are currently your only Auzgrip option...View Size Range Comparison Chart (PDF)

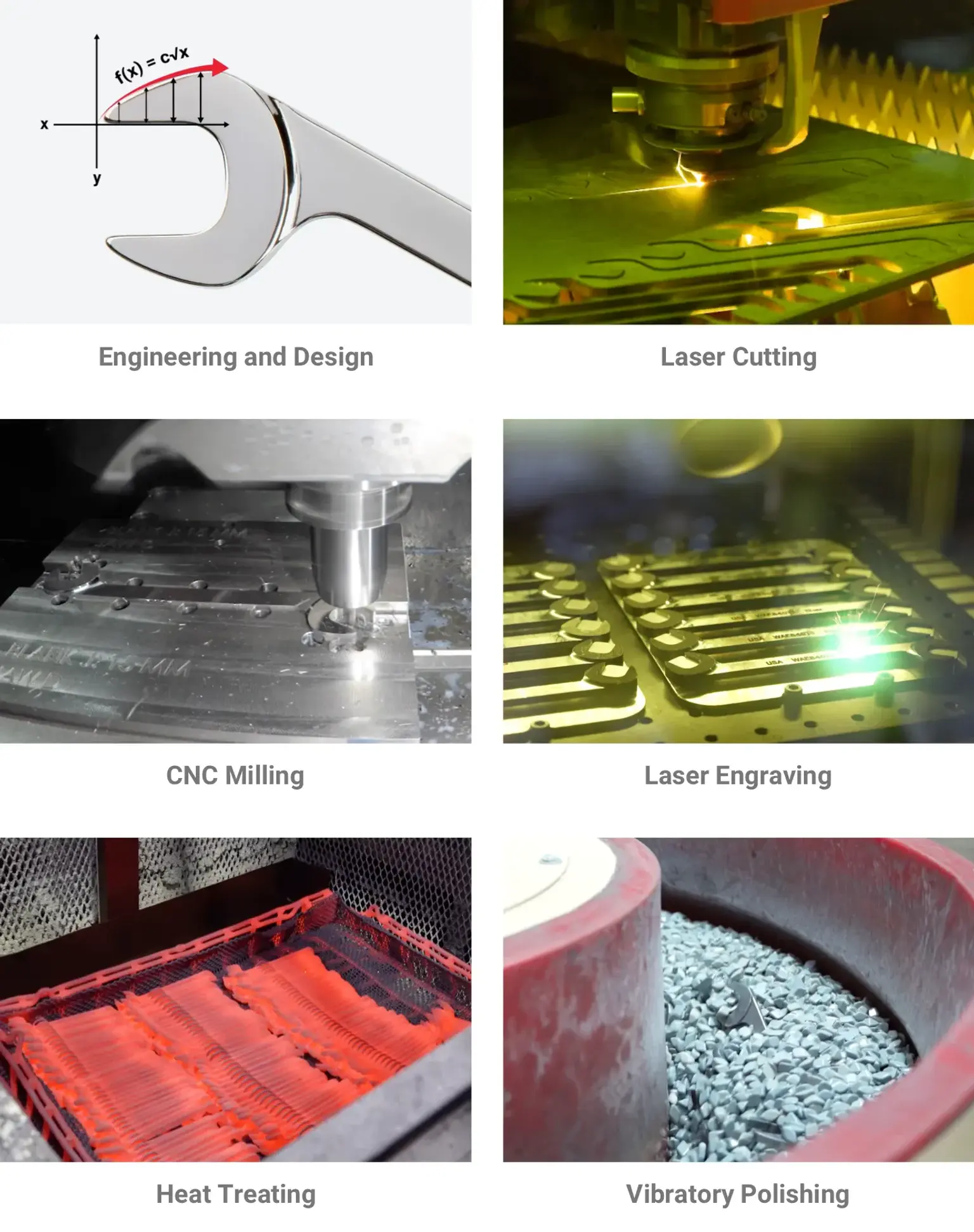

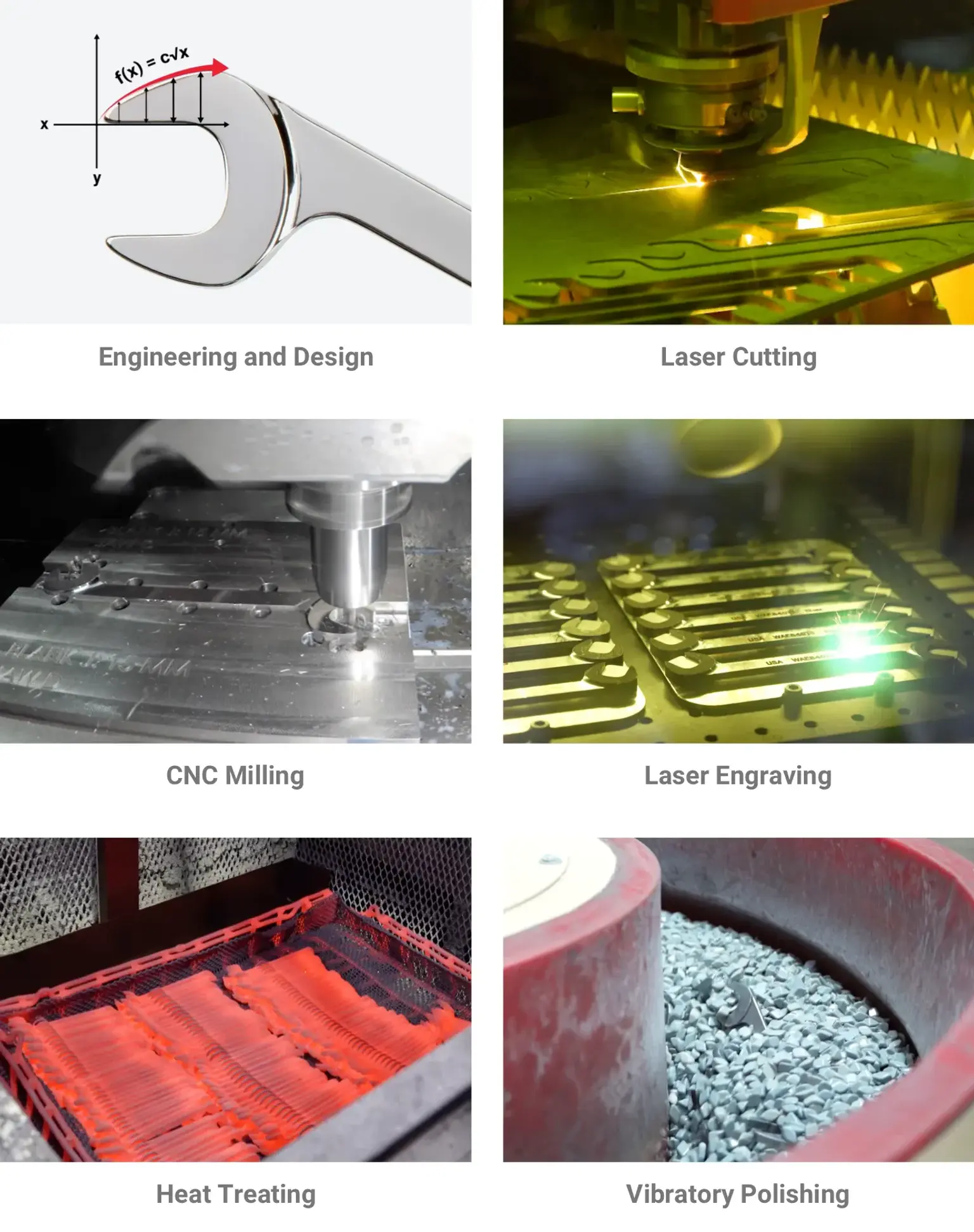

All four access wrenches are manufactured in Michigan using similar processes. Most of the steps occur in our Grand Rapids facility, where we machine, laser mark, vibratory polish, abrasive blast, and nickel plate each wrench.